Abstract

Gunda Gundo orange fruits are cultivated in abundance in the northern region of Ethiopia. Their peels are rich in carotenoid content and could seve as a potential feedstock for natural dye extraction. The aim of this study is to valorize Gunda Gundo orange (Citrus sinensis) peels (GGOP) for dye synthesis followed by its application on dyeing cotton fabric. The natural dye extracted from this renewable biomass feedstock, could reduce environmental contamination, contribute to energy saving and in addition, improvise the livelihood of the farmers cultivating this variety of oranges. The dye extraction was performed using the soxhlet extraction method, in which the effect of extraction temperature (65°C, 72.5°C, 80°C), extraction time (1.5h, 3.25h, 5h) and GGOP to ethanol ratio (0.05g/mL, 0.075g/mL, 0.1g/mL) was studied and optimized by a three-variable, three-level Box–Behnken design using Response Surface Methodology (Design experiment software version 11). A maximum yield of natural dye (40.11%) was achieved at 0.066g/mL GGOP to ethanol ratio at 4.995 h and 79.97°C with a high combined desirability. The high-performance liquid chromatography analysis showed a peak for Gunda Gundo orange peel powder based carotenoid (GGC) dye at Rt value of 2.005 with 3.423 mg/mL dye concentration. Further characterization using Fourier-transform infrared spectroscopy showed the presence of phenols, alkanes and amines. The GGC dye produced were applied onto cotton fabric, using Na2CO3 as fixative. Color dyeing and testing were carried out with data color tool analysis (L*, a*, b*) and fastness properties were investigated according to the American Association of Textile Chemists and Colorists (AATCC-61) and the International Organization for Standardization crocking ISO 105 X12 methods. The washing fastness and rubbing fastness for 4% GGC dyed fabric was higher than that of 1% and 2% GGC dyed fabric. The dyed cotton sample from 4% GGC concentration was red, as shown by the International Commission on Illumination CIELAB color space (CIE L*a* b*). The value of a* (redness) obtained in dyed cotton fabric was as well higher than 1% and 2% GGC. The dye exhibited a good color strength and this suffices the valorization of locally available Gunda Gundo orange peels for natural dye synthesis.

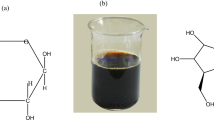

Graphical abstract

Similar content being viewed by others

References

Anuradha Jabasingh S (2019) In search of natural dyes towards sustainability from the regions of Africa (Akebu-Lan), In Mohd Shabbir: Textiles and clothing, Wiley online library, Scrivener publishing LLC, USA, pp. 27-43.

Ababa FA (2018) Ethiopia fresh fruits market update report. Central Statistics Agency (CSA) and Ethiopian Revenue & Customs Authority, Addis Ababa, Ethiopia, pp. 1-8.

Berhanu M, Anuradha Jabasingh S, Kifile Z (2017) Expanding sustenance in Ethiopia based on renewable energy resources—a comprehensive review. Renew Sust Energ Rev 75:1035–1045

Anna H, Christian RV (2003) The potential use of organically grown dye plants in the organic textile industry. Experiences and results on the cultivation and yields of dyers chamomile (Anhemis tinctoria L.), Dyers Knotweed (Polygonum tinctoria Ait.) and Weld (Reseda luteola L). J Sustain Agric 23:17–40

Anuradha Jabasingh S, Pallavi S, Yimam A (2016) Enviro-friendly biofinishing of cotton fibers using Aspergillus nidulans AJSU04 cellulases for enhanced uptake of Myrobalan dye from Terminalia chebula. Dyes Pigments 129:129–140

Cristea D, Vilarem G (2006) Improving light fastness of natural dyes on cotton yarn. Dyes Pigments 70:238–245

Samant L, Jose S, Rose NM, Shakyawar DB (2021) Antimicrobial and UV protection properties of cotton fabric using enzymatic pretreatment and dyeing with Acacia Catechu. J Nat Fibers 18:1–11

Macías-Sánchez JM, Fernandez-Sevilla FG, Acién Fernández MC, Cerón G, Grima EM (2010) Supercritical fluid extraction of carotenoids from Scenedesmus Almeriensis. Food Chem 113:928–935

Pandey R, Patel S, Pandit P, Nachimuthu S, Jose S (2018) Colouration of textiles using roasted peanut skin—an agro processing residue. J Clean Prod 172:1319–1326

Jose S, Pandit P, Pandey R (2019) Chickpea husk—a potential agro waste for coloration and functional finishing of textiles. Ind Crop Prod 142:111833

Neha G, Vidya P (2011) Extraction and application of natural dye preparations from the floral parts of Woodfordia fruticose (Linn.) Kurz. Indian J Nat Prod Resour 2:403–408

Sun Y, Liu D, Chen J, Ye X, Yu D (2011) Effects of different factors of ultrasound treatment on the extraction yield of the all-trans-β-carotene from citrus peels. Ultrason Sonochem 18:243–249

Hou X, Chen X, Cheng Y, Xu H, Chen L, Yang Y (2013) Dyeing and UV-protection properties of water extracts from orange peel. J Clean Prod 52:410–419

De Santis D, Moresi M (2007) Production of alizarin extracts from Rubia tinctorum and assessment of their dyeing properties. Ind Crop Prod 26:151–162

Chandi GK, Gill BS (2011) Production and characterization of microbial carotenoids as an alternative to synthetic colors: a review. Int J Food Prop 14:503–513

Weber RWS, Anke H, Davoli P (2007) Simple method for the extraction and reversed-phase high-performance liquid chromatographic analysis of carotenoid pigments from red yeasts (Basidiomycota, Fungi). J Chromatography A 1145:118–122

Tsatsaroni E, Liakopoulou-Kyriakides M (1995) Effect of enzymatic treatment on the dyeing of cotton and wool fibres with natural dyes. Dyes Pigments 29:203–209

Ashis KS, Priti A (2009) Application of natural dyes on textiles. Ind J Fibre Text Res 34:384–399

Azmir J, Zaidul ISM, Rahman MM, Sharif KM, Mohamed A, Sahena F, Jahurul MHA, Ghafoor K, Norulaini NAN, Omar AKM (2013) Techniques for extraction of bioactive compounds from plant materials: a review. J Food Eng 117:426–436

Mansour R (2018) Natural dyes and pigments: extraction and applications in: Mohd Yusuf (Ed.) Handbook of renewable materials for coloration and finishing, Scivener Publishing LLC, USA, pp. 75-102.

Domínguez-Rodríguez G, Marina ML, Plaza M (2017) Strategies for the extraction and analysis of non-extractable polyphenols from plants. J Chromatogr A 1514:1–15

Aga WS, Fantaye SK, Anuradha Jabasingh S (2020) Biodiesel production from Ethiopian ‘Besana’ - Croton macrostachyus seed: characterization and optimization. Renew Energy 157:574–584

Myers RH, Montgomery DC (1995) Surface methodology: process and product, optimization using designed experiments, 1st edn. Wiley Interscience, New York

Kumar CS, Dhinakaran M (2017) Extraction and application of natural dyes from orange peel and lemon peel on cotton fabrics. Int Res J Eng Technol 4:237–238

Mansour H (2013) Textile dyeing: environmental friendly osage orange extract on protein fabrics, eco-friendly textile dyeing and finishing in: Melih Günay (Ed.) Eco-friendly textile dyeing and finishing, IntechOpen, UK.

Aravantinos-Zafiris G, Oreopoulou V, Tzia C, Thomopoulos CD (1992) Utilisation of orange by products-orange peel carotenoids. J Sci Food Agric 59:77–79

Lin Y, Warnakulasuriya MA, Fernando DB, Margaret B, Charles SB, Coorey VJR (2016) Effect of extraction method and ripening stage on banana peel pigments. Int J Food Sci Technol 51:1449–1456

IPGRI (2000) Informe anual 1999, International Plant Genetic Resources Institute, ISBN 92-9043-460-0 IPGRI, Via delle Sette Chiese 142, 00145, Rome, Italy, pp.37.

Haji A (2019) Natural dyeing of wool with henna and yarrow enhanced by plasma treatment and optimized with response surface methodology. The Journal of the Textile Institute 111:467–475

Adeel S, Rehman F-U, Hameed A, Habib N, Kiran S, Zia KM, Zuber M (2018a) Sustainable extraction and dyeing of microwave-treated silk fabric using Arjun bark colorant. J Nat Fibers 17:1–14

Iqbal J, Bhatti IA, Adeel S (2008) Effect of UV radiation on dyeing of cotton fabric with extracts of henna leaves. Indian J Fibre Text Res 33:157–162

Haji A (2017) Improved natural dyeing of cotton by plasma treatment and chitosan coating. Optimization by response surface methodology. Cellul Chem Technol 51:975–982

Baaka N, Mahfoudhi A, Haddar W, Mhenni MF, Mighri Z (2017) Green dyeing process of modified cotton fibres using natural dyes extracted from Tamarix aphylla (L.) Karst. leaves. Nat Prod Res 31:22–31

Adeel S, Zuber M, Rehman F, Zia KM (2018b) Microwave-assisted extraction and dyeing of chemical and bio-mordanted cotton fabric using harmal seeds as a source of natural dye. Environ Sci Pollut Res Int 25:11100–11110

Zia KM, Adeel S, Rehman F-U, Aslam H, Khosa MK, Zuber M (2019) Influence of ultrasonic radiation on extraction and green dyeing of mordanted cotton using neem bark extracts. J Ind Eng Chem 77:317–322

Işmal OE, Yildirim L, Esen O (2014) Use of almond shell extracts plus biomordants as effective textile dye. J Clean Prod 70:61–67

Batool F, Iqbal N, Azeem M, Adeel S, Ali M (2019) Sustainable dyeing of cotton fabric using black carrot (Daucus carota L.) plant residue as a source of natural colorant. Pol J Environ Stud 28:3081–3087

Adeel S, Ali S, Bhatti IA, Zsila F (2009) Dyeing of cotton fabric using pomegranate (Punica granatum) aqueous extract. Asian J Chem 21:3493–3499

Zuber M, Adeel S, Rehman F-U, Anjum F, Muneer M, Abdullah M, Zia KM (2020) Influence of microwave radiation on dyeing of bio-mordanted silk fabric using neem bark (Azadirachta indica) based tannin natural dye. J Nat Fibers 17:1410–1422

Haji A, Shoushtari AM (2011) Natural antibacterial finishing of wool fiber using plasma technology. Industria Textila 62:244–247

Haji A, Khajeh MM, Akbarpour R (2015) Optimization of β-cyclodextrin grafting on wool fibers improved by plasma treatment and assessment of antibacterial activity of berberine finished fabric. J Incl Phenom Macrocycl Chem 81:121–133

Haji A, Mehrizi MK, Sharifzadeh J (2016) Dyeing of wool with aqueous extract of cotton pods improved by plasma treatment and chitosan: optimization using response surface methodology. Fiber Polym 17:1480–1488

Haji A, Naebe M (2020) Cleaner dyeing of textiles using plasma treatment and natural dyes: a review. J Clean Prod 265:121866

Islam GN, Ke G, Haque ANMA, Islam MA (2017) Effect of ultrasound on dyeing of wool fabric with acid dye. Int J Ind Chem 8:425–431

Ismal EO, Yıldırım L, OzdoGan E (2015) Valorisation of almond shell waste in ultrasonic bio-mordanted dyeing: alternatives to metallic mordants. J Text Inst 106:343–353

Ben TM, Haddar W, Meksi N, Guesmi A, Mhenni MF (2016) Improving dyeability of modified cotton fabrics by the natural aqueous extract from red cabbage using ultrasonic energy. Carbohydr Polym 154:287–295

Ben TM, Meksi N, Attia HE, Guesmi A, Ben JH, Mhenni MF (2017) Ultrasonic extraction of Parthenocissus quinquefolia colorants: extract identification by HPLC-MS analysis and cleaner application on the phytodyeing of natural fibres. Dyes Pigments 141:103–111

AOAC (2000) Official methods of analysis of AOAC International, 17th ed. Association of Analytical Communities, Gaithersburg, MD, USA.

AOAC (1995) Official methods of analysis of AOAC International, 16th edn. Association official analytical chemists, Washington DC, USA

Nisperos-Carriedo MO, Shaw PE (1990) Comparison of volatile flavor components in fresh and processed orange juices. J Agric Food Chem 38:1048–1052

Anuradha Jabasingh S (2011) Utilization of pretreated coir pith for the optimized bioproduction of cellulase by Aspergillus nidulans. Int Biodeterior Biodegrad 65:1150–1160

Sinha K, Saha PD, Datta S (2012) Response surface optimization and artificial neural network modeling of microwave assisted natural dye extraction from pomegranate rind. Ind Crop Prod 37:408–414

Espinosa-Morales J, Reyes BH, Azamar-Barrios JA (2012) Characterization of a natural dye by spectroscopic and chromatographic techniques. Mater Resear Soc 1374:1–14

Alam Md S, Khan GMA, Razzaque SMA, Hossain MJ, Minhaz-ul-Haque M, Zebsyn S (2008) Dyeing of cotton fabrics with reactive dyes and their physico-chemical properties. Indian J Fibre Text 33:58–65

Lagergren S (1898) About the theory of so-called adsorption of soluble substances. K Sven Vetenskapsakad Handl 24:1–39

Ado A, Yahaya H, Kwalli AA, Abdulkadir RS (2014) Dyeing of textiles with eco-friendly natural dyes: a review. Int J Environ Monit Assess 1:76–81

AATCC61 (2013)Test method for colorfastness to laundering: accelerated, American Association of Textile Chemists and Colorists (AATCC), North Carolina, USA, pp.1-6.

ISO 105 X12 (2016) Textiles—tests for colour fastness—part X12: colour fastness to rubbing, Tests for colored textiles and colorants, 6th edn., International Organization for Standardization, Geneva, Switzerland, pp.1-5.

Ali S, Hussain T, Nawaz R (2009) Optimization of alkaline extraction of natural dye from Henna leaves and it’s dyeing on cotton by exhaust method. J Clean Prod 17:61–66

Tariq MA, Faisal M, Saquib M, Muneer M (2008) Heterogeneous photocatalytic degradation of an anthraquinone and a triphenylmethane dye derivative in aqueous suspensions of semiconductor. Dyes Pigments 76:358–365

Kumar JA, Amarnath DJ, Anuradha Jabasingh S, Senthil KP, Vijai A, Narendra KG, Karthick RN, Krithiga T, Samson S, Purna PS, Yuvarajan D (2019) One pot green synthesis of nano-magnesium oxide-carbon composite: preparation, characterization and application towards anthracene adsorption. J Clean Prod 237:1–18

Rabiei N, Kish MH, Amirshahi SH, Radjabian M (2012) Kinetic and thermodynamic parameters of dyeing of polypropylene/clay composite fibers using disperse dye. Dyes Pigments 94:386–392

Anuradha Jabasingh S (2018) Ecofriendly bio-finishing and dyeing of natural fibers in: Handbook of textile coloration and finishing, M. Shahid, G. Chen, R-C.Tang (Ed.), Studium Press LLC, USA, pp. 37-53.

Santos CM, Dweck J, Viotto RS, Rosa AH, Morais LCD (2015) Application of orange peel waste in the production of solid biofuels and biosorbents. Bioresour Technol 196:469–479

Acknowledgements

The authors are thankful to MAA-garment and textile Company, Quiha, Mekelle, Ethiopia, for the contribution of cotton fabric. The first two authors are thankful to Addis Ababa Institute of Technology, Addis Ababa University, Ethiopia (grant no. M.Sc-RG/ GSR/2460/10) for the financial and technical support provided. The time, efforts, comments, and recommendations of the anonymous reviewers and the Editor-in-Chief, Martin Kaltschmitt, are greatly acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Systematic valorization of Gunda Gundo orange peels for dye synthesis

• Intense characterization of the GGC dye by UV, FT-IR and HPLC

• Competent application (AATCC-61, Crocking ISO 105 X12) on cotton fabric

Rights and permissions

About this article

Cite this article

Werede, E., Jabasingh, S.A., Demsash, H.D. et al. Eco-friendly cotton fabric dyeing using a green, sustainable natural dye from Gunda Gundo (Citrus sinensis) orange peels. Biomass Conv. Bioref. 13, 5219–5234 (2023). https://doi.org/10.1007/s13399-021-01550-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01550-6