Abstract

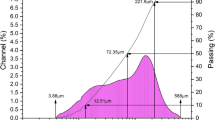

Dietary fibers (DF) are separated by different methods, of which the dry processing method is relatively unexplored. For the first time, a dry process (elutriator) is reported to be used to recover DF from fruit peel. In this study, an elutriator was designed to separate DF from sweet lime peel (SLP) powder. Separated product was analyzed for total dietary fiber (TDF), and micrographs were taken using scanning electron microscopy (SEM) to understand the surface morphology. Effect of particle size and terminal velocity on the separation of DF was studied. Physical properties that are deterministic in the efficient separation of DF by dry separation methods are particle bulk density, equivalent spherical diameter, sphericity, and terminal velocities of fibers. Further, particle size, terminal velocity, and other operating parameters were optimized using Response Surface Methodology (RSM). By using an elutriator, the concentration of TDF increased from 62.15 to 82.26%. RSM models applied successfully for TDF and yield. A relationship between independent parameters like air velocity, particle size, and dependent parameters like yield and TDF recovered was developed. The generalized relationship was validated on SLP and predicted air velocity of 2.04 m/s and particle size 926.85 micron, which is found to meet experimental results as the best conditions to operate elutriator. A general model to predict air velocity to separate DF for the given peel waste based on particle bulk density, equivalent spherical diameter, and sphericity is proposed and validated.

Similar content being viewed by others

References

Li YO, Komarek AR (2017) Dietary fibre basics: health , nutrition , analysis , and applications. Food Qual Saf 47–59. https://doi.org/10.1093/fqs/fyx007

(2000) The definition of dietary fiber. https://www.cerealsgrains.org/initiatives/definitions/Documents/DietaryFiber/DFDef.pdf. Accessed 25 April 2021

Yang J, Xiao A, Wang C (2014) Novel development and characterisation of dietary fibre from yellow soybean hulls q. FOOD Chem 161:367–375. https://doi.org/10.1016/j.foodchem.2014.04.030

Tharanathan SNR, NKR, KSMSR·RN (2004) Dietary fiber from coconut residue: effects of different treatments and particle size on the hydration properties. Eur Food Res Technol 563–567. https://doi.org/10.1007/s00217-004-0889-2

Maphosa Y, Jideani VA (2015) Dietary fiber extraction for human nutrition - a review. Food Rev Int 1–45. https://doi.org/10.1080/87559129.2015.1057840

Assatory A, Vitelli M, Reza A, Legge RL (2019) Dry fractionation methods for plant protein, starch and fi ber enrichment : a review. Trends Food Sci Technol 86:340–351. https://doi.org/10.1016/j.tifs.2019.02.006

Slavin JL (2005) Dietary fiber and body weight. Nutrition 21:411–418. https://doi.org/10.1016/j.nut.2004.08.018

United Nations, Department of Economic and Social Affairs, Population Division (2019) World Population Prospects 2019: Highlights (ST/ESA/SER.A/423). https://population.un.org/wpp/Publications/Files/WPP2019_Highlights.pdf. Accessed 25 April 2021

Huang L, Ding X, Zhao Y et al (2017) Modification of insoluble dietary fiber from garlic straw with ultrasonic treatment. J Food Process Preserv 1–8. https://doi.org/10.1111/jfpp.13399

Hussain S, Ivi J, Bhat R (2020) Dietary fiber from underutilized plant resources — a positive approach for valorization of fruit and vegetable wastes. Sustain Rev 12:1–30

Sagar NA, Pareek S, Sharma S et al (2018) Fruit and vegetable waste : bioactive compounds, their extraction, and possible utilization. Compr Rev food Sci food Saf 17:512–531. https://doi.org/10.1111/1541-4337.12330

de Moraes CT, Jablonski A, de Oliveira RA et al (2013) Dietary fiber from orange byproducts as a potential fat replacer. LWT - Food Sci Technol 53:9–14. https://doi.org/10.1016/j.lwt.2013.02.002

Bakirci S, Dagdemir E, Boran OS, Hayaloglu AA (2016) The effect of pumpkin fibre on quality and storage stability of reduced-fat set-type yogurt. Int J Food Sci Technol 1–8. https://doi.org/10.1111/ijfs.13264

Mishra A, Chakravarty I, Mandavgane S (2021) Current trends in non-dairy based synbiotics. Crit Rev Biotechnol 0:1–24. https://doi.org/10.1080/07388551.2021.1898329

Srinivasan R, Moreau RA, Rausch KD, Belyea RL (2005) Separation of fiber from distillers dried grains with solubles ( DDGS ) using sieving and elutriation. Cereal Chem 82:528–533. https://doi.org/10.1094/CC-82-0528

Srinivasan R, Singh V (2008) Physical properties that govern fiber separation from distillers dried grains with solubles ( DDGS ) using sieving and air classification. Sep Purif Technol 61:461–468. https://doi.org/10.1016/j.seppur.2008.01.002

Huang Y, Ma Y (2015) The effect of extrusion processing on the physiochemical properties of extruded orange pomace. FOOD Chem 192:363–369. https://doi.org/10.1016/j.foodchem.2015.07.039

Uhl JB, Lamp BJ (1966) Pneumatic separation of grain and straw mixtures. Pneum Sep Grain Straw Mix 9:244–246

Becker HA (1959) The effects of shape and reynolds number on drag in the motion of a freely oriented body in an infinite fluid ’. Can J Chem Eng 37:85–91

Myers RH, Montgomery DC (2002) Response surface methodology, process and project optimization using designed experiments

Funding

This study is carried out with financial support from the Department of Science and Technology (DST) of India (DST-SP/YO/039/2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khanpit, V.V., Mandavgane, S.A. & Tajane, S.P. Waste to wealth-recovery of total dietary fibers from waste peel: a generalized model for predicting operating parameters. Biomass Conv. Bioref. 13, 9155–9164 (2023). https://doi.org/10.1007/s13399-021-01791-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-021-01791-5