Abstract

In this study, the extraction of oil from pinecone of Pinus brutia was evaluated by supercritical CO2 (Sc-CO2) and Soxhlet extraction methods. The quercetin, rutin and kaempferol (QRK) contents of oil were analyzed one by one via HPLC. The rutin compound investigated in this study has the potential to be a drug against the COVID 19 virus. SEM and BET analysis were performed to observe the structural change and increase in surface area after Sc-CO2 extraction. The operating conditions were investigated in the range of 35–65 °C temperatures, 140–220 bar of pressures, 0.30–1.00 mm of mean particle sizes, 3–7 l/min of CO2 flow rates, 0–8% w/w co-solvent and 30–150 min extraction periods. When the results obtained by the Sc-CO2 method were compared with the results of Soxhlet extraction method, the maximum recovery of total QRK was found 4.18% in co-solvent-free studies and 30.94% in co-solvent-added Sc-CO2 studies. Sc-CO2 extraction results of Q, R, and K were found as 14.75 ± 1.08 µg/g, 14.23 ± 1.27 µg/g, and 15.70 ± 1.13 µg/g pinecone, respectively. Soxhlet extraction results of Q, R, and K were found as 36.43 ± 2.26 μg/g, 57.19 ± 3.81 μg/g, and 50.80 ± 2.79 μg/g pinecone, respectively. The maximum amount of QRK was found as 44.68 ± 2.89 μg/g pinecone by Sc-CO2 method via adding 8% ethanol by mass and as 144.42 ± 5.39 μg/g pinecone by Soxhlet method. According to the reference Soxhlet method efficiency, the Sc-CO2 extraction recovery was found as 30.94%.

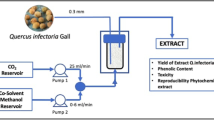

Graphic abstract

Similar content being viewed by others

Introduction

In the past, forestry wastes could be used as fuelwood or ornament, but nowadays, they gather considerable attention to be used as a source to obtain bioactive compounds because of their high potential of bioactive content. There are approximately 200 pine species recognized as coniferous trees in the genus Pinus within the family of Pinaceae. The characteristic specifications of these pines are nearly equal to each other in terms of scales and shapes (Turley et al. 2006). Pinus brutia belongs to this family and is a widespread species in Eastern Mediterranean Region. Pinus brutia is a coniferous and evergreen tree, growing to 7–20 m tall. This potential of Pinus brutia could be considered as a readily available resource and could be easily collected and utilized for bioactive compound production. Pinus brutia has rich terpenoids, flavonoids, lignands, polyphenolics and oily content. Pinecone of Pinus brutia has also valuable and curative phytochemical compounds. Because of increasing worldwide recycling tendency, this source can be used as a raw material to produce valuable extracts and bioactive substances.

In the literature, four pine species have phenolic compounds and flavonoids in young needles (Karapandzova et al. 2015). There are a lot of components that have been determined as VOC content in six coniferous tree species including Pinus brutia analyzed by the solid phase micro-extraction (Ozgenc et al. 2017a). Hydrodistillation extracts of Pinus brutia and Pinus pinea were studied in vitro for their antioxidant, phytotoxic, insecticidal and antimicrobial activities (Ulukanli et al. 2014). Additionally, antioxidant components of Pinus elliottii needles were studied to identify optimum conditions of the microwave-assisted extraction (Ouyang et al. 2017). In another study, Pinus brutia showed high antifungal activity (Ozgenc et al. 2017b). The highest total phenolic content was found in methanol extracts of Pinus brutia in the four other Pinus species (Yener et al. 2014). This kind of Pinus types is known as curative for myalgia, rheumatic pains, respiratory problems, bronchitis, bronchial asthma, cough, sinusitis, laryngitis, tracheitis, pharyngitis, emphysema, and influenza (Vuorela et al. 2005). Flavonoids have many protective and preventive properties for human health. Apigenin, luteolin, taxifolin, quercetin, kaempferol and genistein were shown to inhibit the ovarian cancer cell growth and strong inhibition to cell proliferation of human ovarian cancer cells (Luo et al. 2008). Rutin (vitamin P) was reported to be a compound that inhibits the viability of ovarian cancer cells and induces apoptosis by endoplasmic reticulum stress signaling pathways (Zhao et al. 2017). In a current silico study, it has been shown that rutin can be used more successfully in the treatment of Covid 19 by inhibiting the main protease on the surface of the COVID 19 virus (Al-Zahrani 2020). Quercetin has been identified as the most active flavonoid. Besides, this flavonoid increases the activity of other flavonoids and it has antimetastatic impacts on gastric cancer cells (Li and Chen 2018). Kaempferol containing diet has beneficial effects, especially for reducing the risk of chronic diseases. Moreover, it increases the defense ability of the body with its antioxidant property against free radicals that lead to the development of cancer (Chen and Chen 2013). This compound is very effective for inhibiting cancer cells, and it modifies different cellular signaling pathways and when compared with common chemotherapy drugs, kaempferol is much less toxic for healthy cells (Ramos 2007), (Zhang et al. 2008). In another study, the compounds of quercetin rutin kaempferol and isorhamnetin in the leaves of Ginkgo biloba were investigated by graphene oxide-assisted ethanol reflux extraction method (Gong et al. 2020) (Fig. 1).

The extraction of some valuable flavonoids from pinecone of Pinus brutia is considered as commercially important research area because of the increase in demand of bioactive compound used as nutraceutical and food preservative.

Besides our research, some studies on trees in the same family are given in this paragraph. The determination of optimization conditions for taxifolin extraction from Pinus nigra (pine bark) via supercritical fluid extraction (SFE) modified with ethanol (Ghoreishi et al. 2016a), and the determination of optimal Sc-CO2 extraction conditions to obtain oil and fatty acids from ponderosa pine wood (yellow pine) (Ritter and Campbell 1991), and suberinic acids, triterpenoids and other beneficial contents from birch bark (Krasutsky 2006) studies are available in the literature. Similarly, the optimization of extraction conditions to produce higher antioxidant was studied from bark of Pinus pinaster via SFE method (Braga et al. 2008). The flavonoid content and antioxidant capacity of different pines from Turkey and Germany were investigated via Sc-CO2 extraction method (Yesil-Celiktas et al. 2009). SFE method is an advantageous and environmentally friendly technique for pharmaceutical, food and cosmetic applications that have high value-added industries. The CO2 required for eco-friendly Sc-CO2 extractions can be produced in a high volume and purity in coal and biomass synthetic natural gas production facilities (Bassano et al. 2020).

To the best of our knowledge, there is no published study in the literature regarding the Sc-CO2 extraction and identification of optimization parameters for the isolation of quercetin, rutin, and kaempferol (expressed as QRK in this study) from pinecone of Pinus brutia or other Pinus species. Moreover, quercetin, rutin, and kaempferol compounds have not been studied in Pinus species via neither Soxhlet nor Sc-CO2 extraction method. As a result of this study, the yields of Soxhlet and Sc-CO2 methods will be compared in terms of obtaining QRK. The primary purpose of this study is to determine the optimization conditions for the maximum amount of oil. The other purpose of this study is to find the maximum QRK amount that can be obtained by working with co-solvent addition under conditions where the QRK efficiency is higher.

Experimental

Materials, reference standards

In this study, fresh and ripe pinecones of Pinus brutia were picked up as a raw material from Gölbaşı region of Ankara, Turkey. Pinecones were downscaled by a laboratory crusher, and then, the crushed sample was dried in the shadow. After drying, the sample was grinded into small size particles by Retsch (Haan, Germany) brand plant grinder and Bosch (Midrand, South Africa) brand coffee grinder. Then, pinecone samples were classified into five different sizes on an average of 0.30 mm, 0.55 mm, 0.65 mm, 0.85 mm, and 1.00 mm. Standard quercetin (≥ 95%) and rutin trihydrate (≥ 95%, referred to as Rutin) from Sigma (Darmstadt, Germany) and kaempferol (≥ 95%) from Cayman (Michigan, USA) were utilized as primer calibration standards. HPLC column was a C-18 RP Sigma (Darmstadt, Germany) column.

Chemicals

Acetonitrile (purity ≥ 99.9%), methanol (purity ≥ 99.9%) and ethanol (purity ≥ 99.9%) were used as mobile phase and solvent. They were purchased from Merck (Gernsheim, Germany). Formic acid (purity ≥ 99.9%) was also supplied from Merck (Gernsheim, Germany) as a buffer for mobile phase. These chemicals were utilized for Soxhlet, Sc-CO2 extraction and HPLC analyses. Siphoned liquid carbon dioxide (99.99%) was supplied from Oksan gas company Ankara, Turkey. Deionized water was produced using SG brand reverse osmosis water purifier system.

HPLC analysis

The separation of individually targeted flavonoid compounds in all extracts was carry out with a HPLC system. This system was Dionex 680 HPLC (California, USA) with UVD 170U detector, P680 quaternary pump and a Sigma C-18 RP type column (100 × 3.0 mm I.D., dp = 2.7 μm). The mobile phase solution was formulated as follows: deionized water/formic acid at 99.9:0.1, v/v (A) and acetonitrile/methanol at 75:25, v/v (B).

Elution gradient program with a constant flow rate of 0.5 ml/min was performed as follows: 0–5 min of 80–20% of A in B, 5–10 min 60–40% of A in B, 10–15 min 30–70% of A in B, 15–20 min 80–20% of A in B. Manual injection loop size was 20 μl. The detection wavelength of UVD 170U detector was 256 nm. This wavelength was chosen suitable for all quercetin rutin and kaempferol UV absorptions. Stock standard solution of QRK was prepared in ethanol as 100 ppm and diluted for calibration curve to 2, 10, 50 ppm as 3-point calibration standards.

Soxhlet extraction

For each Soxhlet extraction, 10 g of powdered 0.3 mm mean particle size Pinus brutia pinecone sample was weighted and placed into the Soxhlet equipment and continuously extracted for 7 h by using 170 ml ethanol as organic solvent. Similar Soxhlet application conditions and recovery calculations were used in the literature (Ghoreishi et al. 2016b). HPLC analysis was used for determination of QRK amounts and recoveries in the ethanolic extracts.

Supercritical CO 2 extraction

The Spe-ed SFE model of Applied Separations brand laboratory-scale SFE equipment was used to extract Pinus brutia pinecone samples throughout this study. The system of this equipment consists of an air compressor, an air-driven liquid CO2 pump, recirculating and cooling bath to cool pressurizing pump, an extractor, a high-pressure liquid pump for co-solvent pumping, temperature-controlled oven, an extract collecting vessel, heated CO2 exit unit, needle valve to arrange output flow rate of CO2 and a flowmeter to monitor the output CO2 flow rate. Throughout all the Sc-CO2 extractions, a 24-ml internal volume extractor was used. The extractor was loaded with 5 g sample of Pinus brutia pinecone, and glass wool was placed above and below the sample in the extractor.

All the extraction studies were performed at 30–150 min collecting time, 140–220 bar in the pressure range, 35–65 °C temperature range, 3–7 l/min CO2 flow range and 0.30–1.00 mm mean particle size ranges. The extracted samples were kept at approximately − 6 °C in a freezer to preserve all chemical content until HPLC analysis. Co-solvent flows were identified according to the flow rate of CO2 by mass, and the effect of ethanol ratios of 2.0%, 3.5%, 5.0%, 6.5% and 8.0% by mass on the extraction efficiency was investigated.

Scanning electron microscopy (SEM) analysis

Topographic surface images of Pinus brutia pinecone samples, which were separated before and after the supercritical CO2 extraction process, were covered for three times with Au–Pd for 180 s to be conductive, and samples were analyzed with Jeol brand JSM-6360 LV model SEM device.

Brunauer–Emmett–Teller (BET) surface area analysis

The surface areas of Pinus brutia pinecone samples, which were separated before and after the supercritical CO2 extraction process, were analyzed to see extraction efficiencies. These samples were weighed as 0.0997 g and 0.0923 g, respectively, and analyzed after the degas process was carried out at 90 °C for 5 h with the Quantachrome Nova 220 model BET device.

Results and discussion

Supercritical CO2 extraction method is a rapid and efficient method to obtain bioactive compounds from plants. Experimental working ranges were determined in the light of the literature. The optimal temperature and dynamic extraction time of Sc-CO2 extraction of taxifolin from Pinus nigra bark were identified as 43 °C and 138 min, respectively (Ghoreishi et al. 2016a). The optimal CO2 flow rate and Sc-CO2 extraction time of quercetin from elaeagnus seeds were identified as 5 l/min CO2 and 120 min, respectively (Nuralin et al. 2017). The process parameters of Pinus brutia pinecone Sc-CO2 extraction were selected as pressure, temperature, mean particle size, CO2 flow rate, co-solvent ratio, and extraction period. Working conditions were determined in the light of these studies and considering the safe working range of the Sc-CO2 extraction device. Ranges of them were selected as 140–220 bar, 35–65 °C, 0.30–1.00 mm, 3–7 l/min CO2, 0–8% co-solvent, 30–150-min extraction period. After the extraction and sample preparation r2 values of calibration curves for quercetin, rutin and kaempferol were calculated by the area data of HPLC analysis as r2:0.9973, r2:0.9904 and r2:0.9909, respectively. The identification and quantification of each target flavonoid were performed by comparing with retention times of characteristic chromatogram of primer standards and samples, and the quantification was calculated one by one. Each analysis was replicated two times. The QRK recovery values of Sc-CO2 extraction method was calculated with Eq. 1:

Extraction time definition with modeling and its effect on recoveries.

Determination of extraction time is very important in terms of energy saving and high recovery. Initial conditions were selected to determine total extraction period as 160 bar, 35 °C, 5 l/min CO2, and 0.30 mm mean particle size. The results of extraction period identification studies and modeling solutions are given in Figs. 3 and 4.

The QRK content of pinecone of Pinus brutia samples was studied experimentally through time. In the light of the obtained experimental values, the possible maximum amount of QRK (Q) was calculated when time approaches infinity and time constant Tau (τ) was calculated for 95% confidence level by using Eq. (3) after solving Eq. (2):

first-order differential equation with initial condition Q (0) = 0.

Solution and general model:

Coefficients (with 95% confidence bounds):

Q \(_{t \to \infty }\) = 6.52 µg/g pinecone (6.311, 6.728), estimated maximum QRK amount, when time approaches infinity.

τ = 114.26 min (98.7, 129.8) (extraction time (τ4) for 98% extraction efficiency and ranges).

R2: 0.9986 (coefficient of correlation) and RMSE: 0.1059 (root mean square error).

Experimentally QRK recovery was obtained as 4.52% (6.5 µg/g pinecone).

It can be seen in Fig. 3 that each detailed amounts of Q, R, K were analyzed from 5 subsamples taken at five-time intervals of 30, 60, 90, 120 and 150 min of an experiment.

As can be seen in Fig. 2, nonlinear regression values were very close to experimental values and R2 value was close to 1. The regression value of time is 114 min to obtain 98% extraction efficiency of QRK; the extraction period was selected as 120 min to be more controlled.

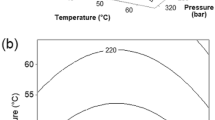

Effect of pressure on extraction recoveries

In order of priority, firstly the effects of pressure to Sc-CO2 extraction were studied for the amount of oil, and QRK flavonoids. Pressure range was investigated between 140 and 220 bar. Initial working temperature, mean particle size, CO2 flow rate and extraction period were specified as 35 °C, 0.55 mm, 5 l/min, 120 min, respectively. QRK recovery was obtained as 3.10%. The experimental results are shown in Fig. 4.

To specify the pressure effect, initial conditions were fixed for the pressure optimization experiments. It can be seen in Fig. 4 that the amount of oil and the amount of QRK increased considerably with increasing pressure. Whereas the maximum oil amount was observed at 220 bar pressure, the maximum QRK amount was observed at 200 bar pressure. Due to oil amount optimization pressure value was selected as 220 bar in the following experiments. The amount of maximum oil and QRK were found as 46.1 ± 2.64 mg oil/g pinecone and 4.48 ± 0.43 µg/g pinecone, respectively. Significant increases in the amount of oil and QRK were observed with the increase in pressure (32% oil, and 89% QRK). In the literature, similar increases in extract yield and isorhamnetin amount with pressure increase were observed (Antunes-Ricardo et al. 2017). The same increase also can be seen in Sc-CO2 application of peach seeds for oil and β-sitosterol extraction (Ekinci and Guru 2014).

Effect of temperature on extraction recoveries

The effects of temperature to Sc-CO2 extraction were studied for the amount of oil and QRK flavonoids. Temperature range was selected and examined between 35 and 65 °C. Working conditions were fixed at 0.55 mm mean particle size, 5 L/min CO2 flow rate, 120-min extraction period and previously optimized 220 bar pressure. The amount of maximum oil and QRK were found as 38.08 ± 3.35 mg oil/g pinecone and 4.11 ± 0.47 µg/g pinecone, respectively. QRK recovery was obtained as 2.84%. The experimental results are shown in Fig. 5.

As can be seen in Fig. 5, when the temperature was increased to 65 °C, the amount of obtained oil from the extraction decreased from 38.08 ± 2.79 mg/g pinecone to 27.08 ± 2.06 mg/g pinecone oil. Similarly, it was observed that the amount of QRK decreased as the temperature increased to 65 °C. When extraction temperature raised from 35 to 55 °C, the density of CO2 decreased and also its solvation power decreased, such as gases. The vapor pressure and solubility in Sc-CO2 of oils and active components increased with increasing temperature. These two impacts identified increase or decrease of obtained oil amount and its active component content. In this study, dominant factor is decreased density of CO2 and its decreased solvating power with increasing temperature. Due to increasing temperature, yields decreased because of falling density and solvating power of Sc-CO2. Similar results have been reported about extracted oils from different natural sources in the literature. It was seen that the amount of nutmeg oil decreased when the temperature increased from 313 to 323 K (Machmudah et al. 2006). In a silybin extraction study from milk thistle by supercritical CO2 extraction, it was observed that the amount of silybin and oil decreased with increasing temperature (Çelik and Gürü 2015). In this step, the optimum working condition for both the amount of oil and QRK was found as 35 °C.

Effect of particle size on extraction recoveries

This effect was investigated for the amount of oil, and QRK. The experiments were conducted according to the mean particle sizes of 0.30, 0.55, 0.65, 0.85 and 1.00 mm, and the experimental results are given in Fig. 6. Working conditions were fixed at 120-min extraction period, 5 l/min CO2, flow rate, and previously optimized 220 bar pressure and 35 °C. The maximum amount of oil and QRK were found as 70.24 ± 5.27 mg oil/g pinecone and 5.64 ± 0.13 µg QRK/g pinecone, respectively. QRK recovery was obtained as 3.91%.

As shown in Fig. 6, When the particle size was reduced, there was an increase in the amount of oil and QRK. When the size of the sample was decreased from 1.00 to 0.30 mm, the amount of oil increased to 98.3%, likewise, the amount of QRK increased to 254.7%. These yield increments are so meaningful for obtaining oil and QRK. When the smaller particle sizes are used, the diffusion pathway of the solvent in the solid phase is shortened, penetration of Sc-CO2 into the solid increases and internal mass transfer resistance decreases; therefore, the extraction recovery increases.

Similar results have been reported about particle size effect on the extraction yield in the literature. With the effect of the decrease in particle size, 105% oil content and 73.3% quercetin increments were measured in Sc-CO2 extraction of elaeagnus seeds (Nuralin et al. 2017). In this step, the optimum working condition for both the amount of oil and QRK was found as 0.30 mm particle size.

Effect of CO 2 flow rate on extraction recovery

After determining optimum conditions for extraction time, pressure, temperature, and particle size as 120 min, 220 bar, 35 °C and 0.30 mm, respectively, the effect of CO2 flow rate was investigated. The effect of supercritical CO2 flow rate for extraction yield was studied for the amount of oil, and QRK. The CO2 flow rate range was selected between 3 and 7 l/min CO2 and investigated at 5 flow rates. Working conditions were fixed according to previous optimizations. The amount of oil and QRK were found as 72.28 ± 4.83 mg oil/g pinecone and 6.03 ± 0.22 µg/g pinecone, respectively. QRK recovery was obtained as 4.17%. The experimental results are shown in Fig. 7.

As seen in Fig. 7, the amount of oil increased by 50.2% with increasing CO2 flow rate from 3 to 7 l/min CO2 and the amount of QRK slightly decreased by 18.2% under the same conditions. The increase in CO2 flow rate results in an increase in the number of CO2 molecules per unit volume of the extractor and an increase in the turbulence between Sc-CO2 and the sample in the extractor. Therefore, inter-molecular interaction increases. When the CO2 flow rate increases, external mass transfer resistance reduces. Therefore, oil extraction recovery increases with increasing CO2 flow rate. However, as can be seen from Fig. 7, the QRK amount decreased under the same conditions. When the oil structure of Pinus brutia pinecone was analyzed, it was determined that it contained 39.6% β-pinene, 31.1% α-pinene and 7.8% Δ3-carene (Tumen et al. 2010). The molecular weight of all these compounds is 136.2 g/mol. The molecular weights of QRK molecules are 302.2, 610.5 and 286.2 g/mol, respectively. It is considered that as the CO2 flow rate increases above a certain value, the contact time becomes insufficient for the extraction of such big molecules. The effect of CO2 flow rate on the yield of peach seed extract yield was observed as 96.1% increment (Ekinci and Guru 2014). As a result of this step, oil amount optimization condition was found as 7 l/min CO2 and QRK amount optimization condition was found as 3 l/min CO2.

Effect of co-solvent adding on extraction recovery

The aim of the co-solvent-added experiments is to reach the maximum amount of QRK. Therefore, these experiments were studied under 120 min, 200 bar, 35 °C, 0.3 mm particle size and 3 l/min CO2 flow rate conditions where the highest QRK amounts observed and can be seen in Figs. 3, 4, 5, 6 and 7. The ethanol was fed as 0.14, 0.23, 0.34, 0.44, 0.55 ml/min flows to provide 2%, 3.5%, 5%, 6.5% and 8% by mass to the extractor besides high-pressure Sc-CO2. Total volume of ethanolic extracts was measured as 13, 21, 33, 39 and 49 ml, respectively. The concentration calculations of flavonoids were performed by using these volume factors.

These experiments were limited to 8% w/w ethanol in order to maintain supercritical conditions and avoid high amounts of ethanol in extracts. These ethanolic extracts were directly analyzed at the HPLC after micro filtration.

As shown in Fig. 8, the amount of QRK increased from 6.03 ± 0.22 to 32.19 ± 1.79 μg/g with an increase of 433.8% with the addition of only 2% ethanol as co-solvent. The addition of 8.0% ethanol was more effective in increasing the amount of QRK. In consequence of this polarity enhancing study, the QRK amount increased by 641% from 6.03 ± 0.22 to 44.68 ± 2.89 μg/g pinecone via 8% w/w ethanol addition as co-solvent; therefore, the highest recovery was obtained as 30.94%.

BET and SEM analyses

BET and SEM analyses were performed to compare the productivity of supercritical CO2 extraction methods. The results of BET and SEM analysis of the same type samples, which were taken before and after Sc-CO2 extraction application, are given in Table 1, Figs. 9 and 10.

When Figs. 9 and 10 were compared, it was seen that the pores of the sample were layered and fuller before the Sc-CO2 extraction; however, after the Sc-CO2 extraction, the inner parts of the layered structures were emptied, and the porosity increased. This increased porosity can also be seen from the BET results with the observed 152.1% increase in surface area.

Comparison of operation conditions of methods and their recoveries

Operation conditions of all the applied extraction methods and the results of QRK amounts, and QRK recoveries are given in Table 2.

This study is the first experimental investigation on the parametric optimization of pinecone of Pinus brutia to identify the amount of its valuable flavonoids via Soxhlet and Sc-CO2 extraction methods. Results showed that the Soxhlet extraction provides a yield of 36.43 ± 2.26 μg quercetin/g, 57.19 ± 3.81 μg rutin/g and 50.8 ± 2.79 μg kaempferol/g pinecone. The sum of these quantities was considered as the extractable amounts of QRK recovery as 144.42 ± 5.39 μg/g pinecone. On the other hand, 8% w/w EtOH-added Sc-CO2 extraction result was a yield of 14.23 ± 1.27 μg quercetin/g, 14.75 ± 1.08 μg rutin/g and 15.70 ± 1.13 μg kaempferol/g pinecone; therefore, maximum QRK amount was 44.68 ± 2.89 µg/g pinecone and optimization parameters were obtained 200 bar pressure, 35 °C, 0.30 mm mean particle size, 3 l/min CO2 flow rate, 120 min and 8% w/w ethanol. The effects of independent parameters on extraction yields are given in Table 3.

Statistical analysis

Study results were expressed as mean ± SD (standard error) of the two measurements. The significant statistical difference throughout the measurements was determined using two-tailed unpaired t-test. Statistical significance considered at p ≤ 0.05 significance level.

Conclusions

In this study pinecone of Pinus brutia, which is abundant and easily procurable, was used as raw material. With this paper, the valuable flavonoid content of the Pinus brutia pinecone was clarified. For the first time in the literature, QRK content of Pinus brutia pinecone was investigated via using Soxhlet and Sc-CO2 extraction processes to compare the results of these methods and to calculate Sc-CO2 recovery. As can be understood from the results of this study, the Sc-CO2 method is not effective as the Soxhlet method with 30.94% QRK recovery; however, it is a preferable method in terms of being environmentally friendly, not leaving toxic residues and short extraction period. It was observed that the amount of oil and QRK flavonoids were parallel in terms of pressure, temperature, particle size, extraction time and co-solvent percentage parameters. The most striking parameter to achieve the highest QRK recovery was found to be percentage of the co-solvent. After 8% w/w ethanol addition as co-solvent, the maximum QRK amount increased from 6.03 ± 0.22 to 44.68 ± 2.89 µg/g by 641% recovery increase from 4.18 to 30.94%. Therefore, Sc-CO2 extractions must be planned with polar co-solvent additions to increase the extract yield of precious compounds such as flavonoids. When comparing the surface areas of the same type and particle size of two samples, which were analyzed before and after Sc-CO2 extraction, the growth in the surface area was measured from 4.39 to 11.07 m2/g with increase of 152.1%. When the SEM analyses performed on two samples with the same type and particle size before and after the Sc-CO2 extraction are compared, it can be seen from Figs. 10 and 11 that the porosity has increased. All these results show that the co-solvent-added Sc-CO2 extraction technique is very useful for extracting oils and flavonoids. QRK optimization parameters were obtained as 200 bar pressure, 35 °C temperature, 0.30 mm particle size and 3 l/min CO2 flow rate, 8% w/w co-solvent ratio, and 120-min extraction period. There are scientific studies showing that rutin is more effective than lopinavir, which is used as a drug against COVID 19 virus (Al-Zahrani 2020). The rutin content of Pinus brutia pinecone was found by Soxhlet and Sc-CO2 methods as 57.19 ± 3.81 µg/g and 14.75 ± 1.08 µg/g, respectively. These amounts are very promising results, showing that Pinus brutia pinecone can be used as a raw material against COVID 19 virus.

These comprehensive experimental optimization results could be utilized by pharmaceutical industry to prepare new drugs or nutraceuticals and by process engineers interested in scaling up SFE extraction systems, which is suitable for flavonoid or antioxidant extraction. Besides, researchers can use these results to improve their recoveries on their own processes.

Data availability

The data and materials of this study are available.

Code availability

No special software was used for this study.

Abbreviations

- Sc-CO2 :

-

Supercritical carbon dioxide

- SFE:

-

Supercritical fluid extraction

- SD:

-

Standard deviation

- p :

-

Significance interval

- HPLC:

-

High-pressure liquid chromatography

- R 2 :

-

Square of correlation coefficient

- τ :

-

Time constant (Tau)

- RMSE:

-

Root mean square error

References

Al-Zahrani AA (2020) Rutin as a promising inhibitor of main protease and other protein targets of COVID-19. Silico Stud Nat Prod Commun. https://doi.org/10.1177/1934578x20953951

Antunes-Ricardo M, Gutierrez-Uribe JA, Guajardo-Flores D (2017) Extraction of isorhamnetin conjugates from Opuntia ficus-indica (L.) Mill using supercritical fluids. J. Supercrit. Fluids 119:58–63. https://doi.org/10.1016/j.supflu.2016.09.003

Bassano C, Deiana P, Vilardi G, Verdone N (2020) Modeling and economic evaluation of carbon capture and storage technologies integrated into synthetic natural gas and power-to-gas plants. Appl Energy. https://doi.org/10.1016/j.apenergy.2020.114590

Braga MEM, Santos RMS, Seabra IJ, Facanali R, Marques MOM, de Sousa HC (2008) Fractioned SFE of antioxidants from maritime pine bark. J Supercrit Fluids 47:37–48. https://doi.org/10.1016/j.supflu.2008.05.005

Chen AY, Chen YC (2013) A review of the dietary flavonoid, kaempferol on human health and cancer chemoprevention. Food Chem 138:2099–2107. https://doi.org/10.1016/j.foodchem.2012.11.139

Çelik HT, Gürü M (2015) Extraction of oil and silybin compounds from milk thistle seeds using supercritical carbon dioxide. J Supercrit Fluids 100:105–109. https://doi.org/10.1016/j.supflu.2015.02.025

Ekinci MS, Guru M (2014) Extraction of oil and beta-sitosterol from peach (Prunus persica) seeds using supercritical carbon dioxide. J Supercrit Fluids 92:319–323. https://doi.org/10.1016/j.supflu.2014.06.004

Ghoreishi SM, Hedayati A, Mohammadi S (2016a) Optimization of periodic static-dynamic supercritical CO2 extraction of taxifolin from Pinus Nigra bark with ethanol as entrainer. J Supercrit Fluids 113:53–60. https://doi.org/10.1016/j.supflu.2016.03.015

Ghoreishi SM, Hedayati A, Mousavi SO (2016b) Quercetin extraction from Rosa damascena Mill via supercritical CO2: neural network and adaptive neuro fuzzy interface system modeling and response surface optimization. J Supercrit Fluids 112:57–66. https://doi.org/10.1016/j.supflu.2016.02.006

Gong QY, Guo ZD, Sun ZH, Gong JG, Wei FY (2020) Graphene oxide-assisted ethanol reflux extraction of total flavonoids from Ginkgo biloba leaves: study of kinetics and mechanism. Chem Pap 74:971–984. https://doi.org/10.1007/s11696-019-00934-3

Karapandzova M, Stefkov G, Cvetkovikj I, Stanoeva JP, Stefova M, Kulevanova S (2015) Flavonoids and other phenolic compounds in needles of Pinus peuce and other pine species from the Macedonian Flora. Nat Prod Commun 10:987–990

Krasutsky PA (2006) Birch bark research and development. Nat Prod Rep 23:919–942. https://doi.org/10.1039/b606816b

Li H, Chen C (2018) Quercetin has antimetastatic effects on gastric cancer cells via the interruption of uPA/uPAR function by modulating NF-b, PKC—ERK1/2 and AMPK. Integr Cancer Ther 17:511–523. https://doi.org/10.1177/1534735417696702

Luo HT, Jiang BH, King SM, Chen YC (2008) Inhibition of cell growth and VEGF expression in Ovarian cancer cells by flavonoids. Nutr Cancer Int J 60:800–809. https://doi.org/10.1080/01635580802100851

Machmudah S, Sulaswatty A, Sasaki M, Goto M, Hirose T (2006) Supercritical CO2 extraction of nutmeg oil: experiments and modeling. J Supercrit Fluids 39:30–39. https://doi.org/10.1016/j.supflu.2006.01.007

Nuralin L, Tosun A, Erol F, Akgun FB, Guru M (2017) Optimisation of quercetin amount via response surface methodology for elaeagnus seeds by supercritical CO2 extraction method. J Fac Eng Archit Gazi Univ 32:1233–1241. https://doi.org/10.17341/gazimmfd.369655

Ouyang H, Hou K, Wang LS, Peng WX (2017) Optimization protocol for the microwave-assisted extraction of antioxidant components from Pinus elliottii needles using response surface methodology. BioResources 12:478–494. https://doi.org/10.15376/biores.12.1.478-494

Ozgenc O, Durmaz S, Celik G, Korkmaz B, Yayli N (2017a) Comparative phytochemical analysis of volatile organic compounds by SPME-GC-FID/MS from six coniferous and nine deciduous tree bark species grown in Turkey. S Afr J Bot 113:23–28. https://doi.org/10.1016/j.sajb.2017.07.004

Ozgenc O, Durmaz S, Yildiz UC, Erisir E (2017b) A comparison between some wood bark extracts: antifungal activity Kastamonu University. J For Fac 17:502–508. https://doi.org/10.17475/kastorman.282637

Ramos S (2007) Effects of dietary flavonoids on apoptotic pathways related to cancer chemoprevention. J Nutr Biochem 18:427–442. https://doi.org/10.1016/j.jnutbio.2006.11.004

Ritter DC, Campbell AG (1991) Supercritical carbon dioxide extraction of southern pine and ponderosa pine. Wood Fiber Sci 23:98–113

Tumen I, Hafizoglu H, Kilic A, Donmez IE, Sivrikaya H, Reunanen M (2010) Yields and constituents of essential oil from cones of Pinaceae spp. Nativ Grown Turk Mol 15:5797–5806. https://doi.org/10.3390/molecules15085797

Turley DB, Chaudhry Q, Watkins RW, Clark JH, Deswarte FEI (2006) Chemical products from temperate forest tree species—developing strategies for exploitation. Ind Crops Prod 24:238–243. https://doi.org/10.1016/j.indcrop.2006.06.016

Ulukanli Z, Karaborklu S, Bozok F, Ates B, Erdogan S, Cenet M, Karaaslan MG (2014) Chemical composition, antimicrobial, insecticidal, phytotoxic and antioxidant activities of Mediterranean Pinus brutia and Pinus pinea resin essential oils Chinese. J Nat Med 12:901–910. https://doi.org/10.3724/sp.J.1009.2014.00901

Vuorela S et al (2005) Preclinical evaluation of rapeseed, raspberry, and pine bark phenolics for health-related effects. J Agric Food Chem 53:5922–5931. https://doi.org/10.1021/jf050554r

Yener HO, Saygideger SD, Sarikurkcu C, Yumrutas O (2014) Evaluation of antioxidant activities of essential oils and methanol extracts of Pinus Species. J Essent Oil Bear Plants 17:295–302. https://doi.org/10.1080/0972060x.2014.895164

Yesil-Celiktas O, Otto F, Parlar H (2009) A comparative study of flavonoid contents and antioxidant activities of supercritical CO2 extracted pine barks grown in different regions of Turkey and Germany. Eur Food Res Technol 229:671–677. https://doi.org/10.1007/s00217-009-1101-5

Zhang YQ, Chen ARY, Li M, Chen CY, Yao QZ (2008) Ginkgo biloba extract kaempferol inhibits cell proliferation and induces apoptosis in pancreatic cancer cells. J Surg Res 148:17–23. https://doi.org/10.1016/j.jss.2008.02.036

Zhao J, Li YL, Gao JF, De YS (2017) Hesperidin inhibits ovarian cancer cell viability through endoplasmic reticulum stress signaling pathways. Oncol Lett 14:5569–5574. https://doi.org/10.3892/ol.2017.6873

Acknowledgements

The authors wish to thank Sümeyye Caner and Murat Erbaş for their technical contributions.

Funding

The authors wish to acknowledge the support of the Scientific Research Project Department of Gazi University (Project no: 06/2016–11).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Live experimental objects were not used in this study. The study was conducted in accordance with ethical rules.

Consent to participate

The authors of this article have endorsed this article.

Consent for publication

The publication permission of this article has been given to “Chemical Papers” journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nuralın, L., Gürü, M. & Çete, S. Extraction and quantification of some valuable flavonoids from pinecone of Pinus brutia via Soxhlet and Supercritical CO2 extraction: a comparison study. Chem. Pap. 75, 5363–5373 (2021). https://doi.org/10.1007/s11696-021-01644-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-021-01644-5