Abstract

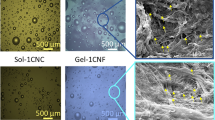

In this work, nanocellulose particles were obtained from eucalyptus fibers by high-pressure homogenization (CNF) and by high-intensity ultrasound (SCNF). The nanocellulose was applied as a solid emulsifier for soybean oil in water (O/W) emulsions. The adding of 0.25–1 wt.% of both CNF and SCNF produced stable O/W emulsions without conventional surfactants. SCNF emulsions showed the highest stability and displayed the narrowest size distribution. Zeta potential values (− 40 to − 70 mV) indicated an electrical barrier to the droplet coalescence. The rheological behavior of O/W emulsions stabilized with CNF and SCNF was described by the Herschel-Buckley model. O/W emulsions produced with nanocellulose particles behave as shear thinning fluid, and their behavior index ranged from 0.33 to 0.68. Both CNF and SCNF emulsions displayed maximum yield stress at a particle concentration of 0.5 wt.% and 0.75 wt.%, respectively. Besides, the prepared O/W emulsions using 0.5 to 1.00 wt.% CNF or SCNF did not showed phase separation until 30 days of rest. The data point out to the feasibility of using nanocellulose as a natural emulsifier, which can replace conventional surfactants.

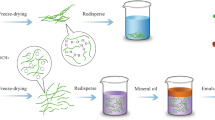

Graphic Abstract

Similar content being viewed by others

Data Availability

The authors confirm total data transparency in this publication.

Code availability

The authors confirm they have used Microsoft word, Microsoft Excel, Origin Lab software and built-in software to the data assessment and analysis.

References

Santos, R.G., Alencar, A.C.: Biomass-derived syngas production via gasification process and its catalytic conversion into fuels by Fischer Tropsch synthesis: a review. Int. J. Hydrogen Energy 45(36), 18114–18132 (2020)

Voloshin, R.A., Rodionova, M.V., Zharmukhamedov, S.K., Veziroglu, T.N., Allakhverdiev, S.I.: Biofuel production from plant and algal biomass. Int. J. Hydrogen Energy 41, 17257–17273 (2016)

Demirbas, A.: Biofuels sources, biofuel policy, biofuel economy and global biofuel projections. Energy Convers. Manag. 49, 2106–2116 (2008)

Li, Q., Wang, Y., Wu, Y.: Flexible cellulose nanofibrils as novel pickering stabilizers: the emulsifying property and packing behavior. Food Hydrocolloids 88, 180–189 (2019)

Li, X., Ding, L., Zhang, Y., Wang, B., Jiang, Y., Feng, X., Mao, Z., Sui, X.: Oil-in-water Pickering emulsions from three plant-derived regenerated celluloses. Carbohyd. Polym. 207, 755–763 (2019)

Gong, X., Wang, Y., Chen, L.: Enhanced emulsifying properties of wood-based cellulose nanocrystals as Pickering emulsion stabilizer. Carbohyd. Polym. 169, 295–303 (2017)

Kalashnikova, I., Bizot, H., Bertoncini, P., Cathala, B., Capron, I.: Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter. 9(3), 952–959 (2013)

Binks, B.P., Lumsdon, S.O.: Effects of oil type and aqueous phase composition on oil-water mixtures containing particles of intermediate hydrophobicity. Phys. Chem. Chem. Phys. 2, 2959–2967 (2000)

Briggs, N., Raman, K.A.Y., Barrett, L., Brown, C., Li, B., Leavitt, D., Aichele, C.P., Crossley, S.: Stable pickering emulsions using multi-walled carbon nanotubes of varying wettability. Colloids Surfaces A: Physicochem. Eng. Aspects 537, 227–235 (2018)

Hu, J.W., Yen, M.W., Wang, A.J., Chu, I.M.: Effect of oil structure on cyclodextrin-based Pickering emulsions for bupivacaine topical application. Colloids Surf., B 161, 51–58 (2018)

Zhu, J.Y., Tang, C.H., Yin, S.W., Yang, X.Q.: Development and characterization of novel antimicrobial bilayer films based on Polylactic acid (PLA)/Pickering emulsions. Carbohyd. Polym. 181, 727–735 (2018)

Klemm, D., Kramer, F., Moritz, S., Lindström, T., Ankerfors, M., Gray, D., Dorris, D.: Nanocelluloses: a new family of nature-based materials. Angew. Chem. Int. Ed. 50, 5438–5466 (2011)

Shaw, DJ.: Introduction to colloid and surface chemistry, 4th edn. Butterworth-Heinemann, Oxford (1992)

De Pretto, C., Giordano, R.L.C., Tardioli, P.W., Costa, C.B.C.: Possibilities for producing energy, fuels, and chemicals from soybean: a biorefinery concept. Waste Biomass Valor. 9, 1703–1730 (2018)

Ojala, J., Sirviö, J.A., Liimatainen, H.: Nanoparticle emulsifiers based on bifunctionalized cellulose nanocrystals as marine diesel oil–water emulsion stabilizers. Chem. Eng. J. 288, 312–320 (2016)

Li, X., Li, J., Gong, J., Kuang, Y., Mo, L., Song, T.: Cellulose nanocrystals (CNCs) with different crystalline allomorph for oil in water Pickering emulsions. Carbohyd. Polym. 183, 303–310 (2018)

Panagopoulou, E., Tsouko, E., Kopsahelis, N., Koutinas, A., Mandala, I., Evageliou, V.: Olive oil emulsions formed by catastrophic phase inversion using bacterial cellulose and whey protein isolate. Colloids Surf. A: Physicochem. Eng. Aspects 486, 203–210 (2015)

Abdul Khalil, H.P.S., Davoudpour, Y., Islam, N., Mustapha, A., Sudesh, K., Dungani, R., Jawaid, M.: Production and modification of nanofibrillated cellulose using various mechanical processes: a review. Carbohyd. Polym. 99, 649–665 (2014)

George, J., Sabapathi, S.N.: Cellulose nanocrystals: synthesis, functional properties, and applications. Nanotechnol. Sci. Appl. 8, 45–54 (2015)

Vallejos, M.E., Felissia, F.E., Area, M.C., Ehman, N.V., Tarrés, Q., Mutjé, P.: Nanofibrillated cellulose (CNF) from eucalyptus sawdust as a dry strength agent of unrefined eucalyptus handsheets. Carbohyd. Polym. 139, 99–105 (2016)

Perrin, L., Gillet, G., Gressin, L., Desobry, S.: Interest of pickering emulsions for sustainable micro/nanocellulose in food and cosmetic applications. Polymers 12, 2385–2399 (2020)

Yang, H., Yan, R., Chen, H., Lee, D.H., Zheng, C.: Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 86, 1781–1788 (2007)

Wang, Y., Wei, X., Li, J., Wang, F., Wang, Q., Zhang, Y., Kong, L.: Homogeneous isolation of nanocellulose from eucalyptus pulp by high pressure homogenization. Ind. Crops Prod. 104, 237–241 (2017)

Pokhrel, N., Vabbina, P.K., Pala, N.: Sonochemistry: science and engineering. Ultrason. Sonochem. 29, 104–128 (2016)

McClements, D.J.: Food Emulsions: Principles, Practice and Techniques. CRC Press, New York (1999)

McClements, D.J., Jafari, S.M.: Improving emulsion formation, stability and performance using mixed emulsifiers: a review. Adv. Coll. Interface. Sci. 251, 55–79 (2018)

Costa, A.L.R., Gomes, A., Tibolla, H., Menegalli, F.C., Cunha, R.L.: Cellulose nanofibers from banana peels as a Pickering emulsifier: High-energy emulsification processes. Carbohyd. Polym. 194, 122–131 (2018)

Schramm, L.L.: Emulsions, foams, and suspensions: fundamentals and applications. Wiley-VCH GmbH & Co., Weinheim (2005)

Derkach, S.: Rheology of emulsions. Adv. Coll. Interface. Sci. 151, 1–23 (2018)

Rosen, M.: Surfactants and interfacial phenomena. John Wiley & Sons (1989)

Zhang, H., Qian, Y., Chen, S., Zhao, Y.: Physicochemical characteristics and emulsification properties of cellulose nanocrystals stabilized O/W pickering emulsions with high -OSO3- groups. Food Hydrocolloids 96, 267–277 (2019)

Santos, R.G., Bannwart, A.C., Briceño, M.I., Loh, W.: Physico-chemical properties of heavy crude oil-in-water emulsions stabilized by mixtures of ionic and non-ionic ethoxylated nonylphenol surfactants and medium chain alcohols. Chem. Eng. Res. Des. 89(7), 957–967 (2011)

Lee, J., Babadagli, T.: Optimal design of pickering emulsions for heavy oil recovery improvement. J. Dispersion Sci. Technol. (2019). https://doi.org/10.1080/01932691.2019.1650754

Yorgancioglu, A., Bayramoglu, E.E.: Production of cosmetic purpose collagen containing antimicrobial emulsion with certain essential oils. Ind. Crops Prod. 44, 378–382 (2013)

Paukkonen, H., Kunnari, M., Laurén, P., Hakkarainen, T., Auvinen, V.V., Oksanen, T., Koivuniemi, R., Yliperttula, M., Laaksonen, T.: Nanofibrillar cellulose hydrogels and reconstructed hydrogels as matrices for controlled drug release. Int. J. Pharm. 532, 269–280 (2017)

Xu, C., Cao, L., Zhao, P., Zhou, Z.: Emulsion-based synchronous pesticide encapsulation and surface modification of mesoporous silica nanoparticles with carboxymethyl chitosan for controlled azoxystrobin release. Chem. Eng. J. 348, 244–254 (2018)

Corral, M.L., Cerrutti, P., Vázquez, A., Califano, A.: Bacterial nanocellulose as a potential additive for wheat bread. Food Hydrocolloids 67, 189–196 (2017)

Solans, C., Solé, I.: Nano-emulsions: formation by low-energy methods. Curr. Opin. Colloid Interface Sci. 17, 246–254 (2012)

Tonoli, G.H.D., Teixeira, E.M., Corrêa, A.C., Marconcini, J.M., Caixeta, L.A., Pereira-da-Silva, M.A., Mattoso, L.H.C.: Cellulose micro/nanofibres from Eucalyptus kraft pulp: preparation and properties. Carbohyd. Polym. 89, 80–88 (2012)

Cheng, Q., Wang, S., Rials, T.: Poly(vinyl alcohol) nanocomposites reinforced with cellulose fibrils isolated by high intensity ultrasonication. Composites: Part A 40, 218–224 (2009)

Nechyporchuk, O., Belgacem, M.N., Pignon, F.: Current progress in rheology of cellulose nanofibril suspensions. Biomacromol 17, 2311–2320 (2016)

Karppinen, A., Saarinen, T., Salmela, J., Laukkanen, A., Nuopponen, M., Seppala, J.: Flocculation of microfibrillated cellulose in shear flow. Cellulose 19, 1807–1819 (2012)

Herrick, F.W., Casebier, R.L., Hamilton, J.K., Sandberg, K.R.: Microfibrillated cellulose: morphology and accessibility. J. Appl. Polyme. Sci. Polym. Symp. 37, 797–813 (1983)

Gruneberger, F., Kunniger, T., Zimmermann, T., Arnold, M.: Rheology of nanofibrillated cellulose/acrylate systems for coating applications. Cellulose 21, 1313–1326 (2014)

Lu, Y., Qian, X., Xie, W., Zhang, W., Huang, J., Wu, D.: Rheology of the sesame oil-in-water emulsions stabilized by cellulose nanofibers. Food Hydrocolloids 94, 114–127 (2019)

Perkins, E.G.: Composition of soybeans and soybean. In: Erickson, D.R. (ed.) Products Practical Handbook of Soya Processing and Utilization, pp. 9–28. Academic Press and AOCS Press, St. Louis (1995)

Wang, S., Cheng, Q.A.: A novel process to isolate fibrils from cellulose fibers by high-intensity ultrasonication, part 1: process optimization. J. Appl. Polym. Sci. 113, 1270–1275 (2009)

Bussemaker, M.J., Zhang, D.: Effect of ultrasound on lignocellulosic biomass as a pretreatment for biorefinery and biofuel applications. Indus. Eng. Chem. Res. 52, 3563–3580 (2013)

Nechyporchuk, O., Belgacem, M.N., Bras, J.: Production of cellulose nanofibrils: a review of recent advances. Ind. Crops Prod. 93, 2–25 (2016)

Lu, H., Zhang, L., Liu, C., He, Z., Zhou, X., NiI, Y.: A novel method to prepare lignocellulose nanofibrils directly from bamboo chips. Cellulose 25, 7043–7051 (2018)

Ewulonu, C.M., Liu, X., Wu, M., Huang, Y.: Ultrasound-assisted mild sulphuric acid ball milling preparation of lignocellulose nanofibers (LCNFs) from sunflower stalks (SFS). Cellulose 26(7), 4371–4389 (2019)

Frone, A.N., Panaitescu, D.M., Donescu, D., Spataru, C.I., Radovico, C., Trusga, R., Somoghi, R.: Preparation and characterization of PVA composites with cellulose nanofibers obtained by ultrasonication. BioResources 6(1), 487–512 (2011)

Vieira, L.B., Casimiro, M.W., Santos, R.G.: Surface tension of aqueous amoxicillin+Peg systems. Colloid Interf. Sci. Commun. 24, 93–97 (2018)

Santos, R.G., Bannwart, A.C., Loh, W.: Phase segregation, shear thinning and rheological behavior of crude oil-in-water emulsions. Chem. Eng. Res. Des. 92, 1629–1636 (2014)

Spinacé, M.A.S., Lambert, C.S., Fermoselli, K.K.G., De Paoli, M.A.: Characterization of lignocellulosic curaua fibres. Carbohyd. Polym. 77, 47–53 (2009)

Azrina, Z.A.Z., Beg, M.D.H., Rosli, M.Y., Ramli, R., Junadi, N., Alam, A.K.M.M.: Spherical nanocrystalline cellulose (NCC) from oil palm empty fruit bunch pulp via ultrasound assisted hydrolysis. Carbohyd. Polym. 162, 115–120 (2017)

Tomak, E.D., Ay, N., Topaloglu, E., Gumuskaya, E., Yildiz, U.C.: An FT-IR study of the changes in chemical composition of bamboo degraded by brown-rot fungi. Int. Biodeterior. Biodegr. 85, 131–138 (2013)

Manzato, L., Rabelo, L.C.A., Souza, S.M., Silva, C.G., Sanches, E.A., Rabelo, D., Mariuba, L.A.M., Simonsen, J.: New approach for extraction of cellulose from tucumã’s endocarp and its structural characterization. J. Mol. Struct. 1143, 229–234 (2017)

Özgenç, O., Durmaz, S., Boyaci, I.H., Eksi-Kocak, H.: Determination of chemical changes in heat-treated wood using ATR-FTIR and FT Raman spectrometry. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 171, 395–400 (2017)

Tibolla, H., Pelissari, F.M., Rodrigues, M.I., Menegalli, F.C.: Cellulose nanofibers produced from banana peel by enzymatic treatment: study of process conditions. Ind. Crops Prod. 95, 664–674 (2017)

Tang, C., Chen, Y., Luo, J., Low, M.Y., Shi, Z., Tang, J., Tam, K.C.: Pickering emulsions stabilized by hydrophobically modified nanocellulose containing various structural characteristics. Cellulose 26(13), 7753–7767 (2019)

Zhai, X., Lin, D., Liu, D., Yang, X.: Emulsions stabilized by nanofibers from bacterial cellulose: new potential food-grade Pickering emulsions. Food Res. Int. 103, 12–20 (2018)

Chumpitaz, L.D.A., Coutinho, L.F., Meirelles, A.J.A.: Surface tension of fatty acids and triglycerides. J. Am. Oil Chem. Soc. 76, 379–382 (1999)

Paximada, P., Tsouko, E., Kopsahelis, N., Koutinas, A.A.: Bacterial cellulose as stabilizer of o/w emulsions. Food Hydrocolloids 53, 225–232 (2016)

Silva, C.E.P., Tam, K.C., Bernardes, J.S., Loh, W.: Double stabilization mechanism of O/W Pickering emulsions using cationic nanofibrillated cellulose. J. Colloid Interface Sci. 574, 207–216 (2020)

Sabet, S.S., Martinez, M., Olson, J.: Shear rheology of micro-fibrillar cellulose aqueous suspensions. Cellulose 23, 2943–2953 (2016)

Lu, Q., Lu, P.M., Piao, J.H., Xu, X.L., Chen, J., Zhu, L., Jiang, J.G.: Preparation and physicochemical characteristics of an allicin nanoliposome and its release behavior. Food Sci. Technol. 57, 686–695 (2014)

Gestranius, M., Stenius, P., Kontturi, E., Sjöblom, J., Tammelin, T.: Phase behaviour and droplet size of oil-in-water Pickering emulsions stabilised with plant-derived nanocellulosic materials. Colloids Surf., A 519, 60–70 (2017)

Yokota, S., Kamada, K., Sugiyama, A., Kondo, T.: Pickering emulsion stabilization by using amphiphilic cellulose nanofibrils prepared by aqueous counter collision. Carbohydr. Polym. 226, 115293 (2019)

Bai, L., Huan, S., Xiang, W., Rojas, O.J.: Pickering emulsions by combining cellulose nanofibrils and nanocrystals: phase behavior and depletion stabilization. Green Chem. 20(7), 1571–1582 (2018)

Fujisawa, S., Togawa, E., Kuroda, K.: Nanocellulose-stabilized Pickering emulsions and their applications. Sci Technol. Adv. Mater. 18(1), 959–971 (2017)

Chevalier, Y., Bolzinger, M.A.: Emulsions stabilized with solid nanoparticles: pickering emulsions. Colloid Surf. A-Physicochem. Eng. Aspects 439, 23–34 (2013)

Hong, I.K., Kim, S.I., Lee, S.B.: Effects of HLB value on oil-in-water emulsions: droplet size, rheological behavior, zeta-potential, and creaming index. J. Ind. Eng. Chem. 67, 123–131 (2018)

Ni, Y., Li, J., Fan, L.: Production of nanocellulose with different length from ginkgo seed shells and applications for oil in water Pickering emulsions. Int. J. Biol. Macromol. 149, 617–626 (2020)

Cunha, A.G., Mougel, J.B., Cathala, B., Berglund, L.A., Capron, I.: Preparation of double Pickering emulsions stabilized by chemically tailored nanocelluloses. Langmuir 30(31), 9327–9335 (2014)

Li, Q., Chen, P., Li, Y., Li, B., Liu, S.: Construction of cellulose-based Pickering stabilizer as a novel interfacial antioxidant: A bioinspired oxygen protection strategy. Carbohydr. Polym. 229, 115395 (2020)

Zanotti, M.A.G., Santos, R.G.: Thixotropic behavior of oil-in-water emulsions stabilized with ethoxylated amines at low shear rates. Chem. Eng. Technol. 42(2), 432–443 (2019)

Jutakridsada, P., Pimsawat, N., Sillanpää, M., Kamwilaisak, K.: Olive oil stability in Pickering emulsion preparation from eucalyptus pulp and its rheology behavior. Cellulose 27, 6189–6203 (2020)

Shafiei-Sabet, S., Martinez, M., Olson, J.: Shear rheology of micro-fibrillar cellulose aqueous suspensions. Cellulose 23, 2943–2953 (2016)

Funding

This work was supported by The Coordination of Superior Level Staff Improvement, CAPES (Grant Number 1751838), the São Paulo Research Foundation, FAPESP (Grant Numbers 2010/17804-7, 2011/00156-5) and the National Council for Scientific and Technological Development, CNPq (Grant Number 310410/2010-0).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors confirm that there are no conflicts of interest associated with this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martins, L.S., dos Santos, R.G. & Spinacé, M.A.S. Properties of Cellulose Nanofibers Extracted from Eucalyptus and their Emulsifying Role in the Oil-in-Water Pickering Emulsions. Waste Biomass Valor 13, 689–705 (2022). https://doi.org/10.1007/s12649-021-01498-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12649-021-01498-8